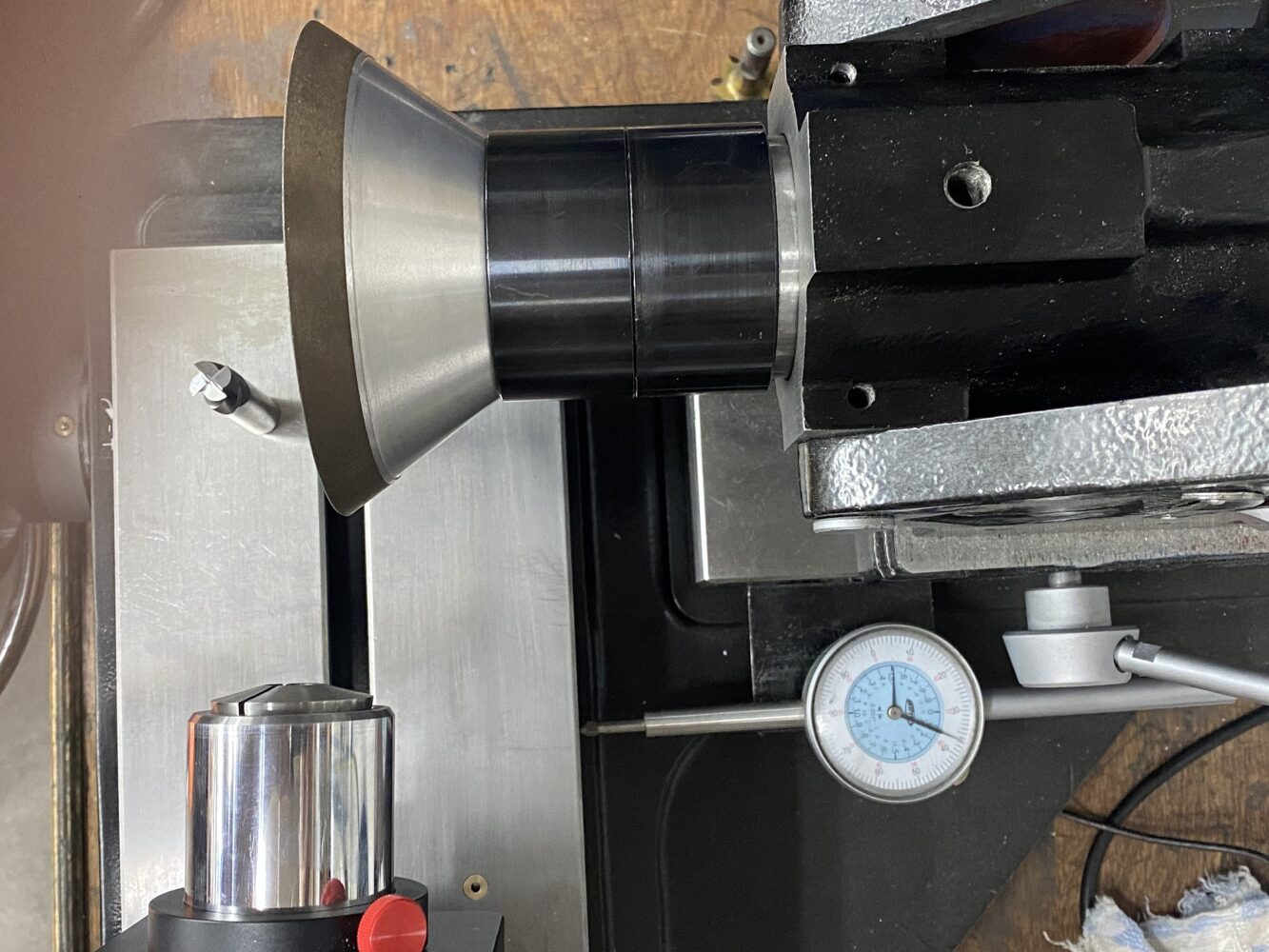

How to easily sharpen ends on a Cuttermaster, Tapered cup Wheel, Edge Grind

115 11V9C wheel at stock height with 2 1/2-inch extension primary angle set to zero

Tool Spindle pivoted 2 degrees clockwise to create an end dish, (recess in the center of the tool so it cuts with the flute tips)

1st operation produce Secondary tilt motor down 3 degrees

During primary operation Produce Gash Stay .005 off-center plunge .015 Max The Spindle extensions are used so there is more vertical lift VS Tilt allowing for better wheel position for center cutting feature production

Contact Us

Contact Us  Phone

Phone