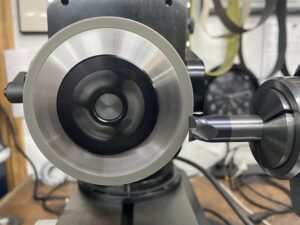

Plated 12V Rim Wheel, Center Cutting Grind ends 2, 3, 4, 5, 6 flute end mills

This Set up makes ends bulletproof. easy to master because of the ability to position the wheel up and down.

It is easy, any size tool, nice finish CBN100 Diamond 180 wheel

Set the tool square to the machine. bring the wheel in to touch the vertical flute Zero the indicator.

Tools can be roughed at 1000 RPM or less keeping heat and dust to a minimum.

Secondary angle: (20 degrees) set wheel height about .800 above center, wheel angle at zero Finishing pass, Primary angle (5 degrees) set the wheel height to center til the wheel back 5 degrees rpm 3000 and you can come all the way past center

to make your primary passes connect.

Simple center cutting Center Gash:

If you want a center cutting 4 flute, During secondary once the final secondary depth is reached– Set X dial to Zero and lock the thumbscrew. When at the center on (on the Y-axis indicator) plunge Flute 1 and 3 feed in x .035 back out to X zero to exit the grind

Contact Us

Contact Us  Phone

Phone