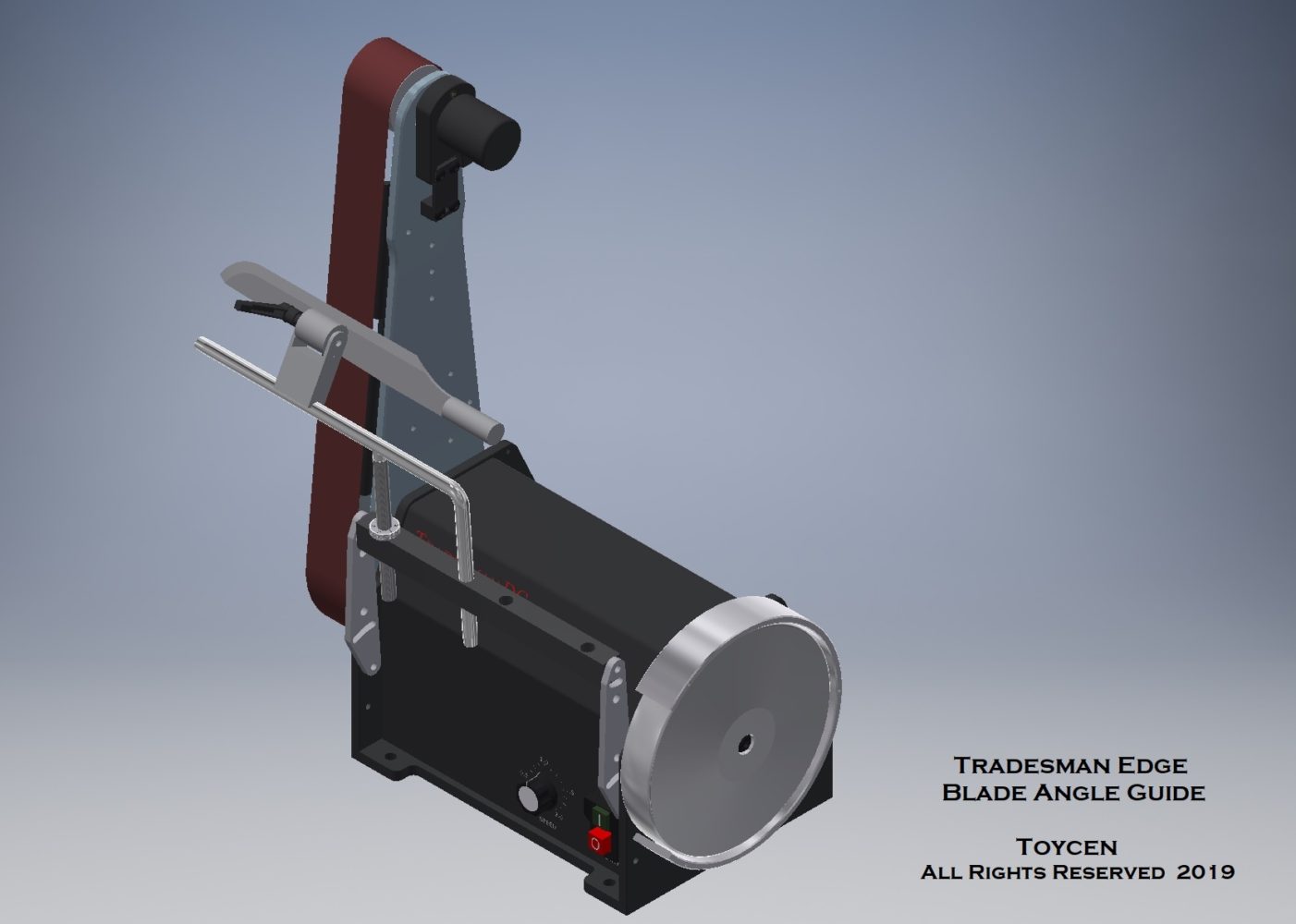

TRADESMAN EDGE – Knife Angle Guide

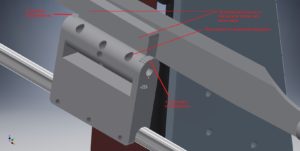

We like this one Fewer part that a multilink arm Better accuracy repeatability faster set up.

Fits on all Tradesman grinders utilize that handy Tormek rail.

Worried about your angles? Do you use a felt wheel to cover angle mismatch

We think you should be able to repeat and angle within a few minutes, Grind at a speed appropriate for finishing, no risk of damage, and only need a strop type effort to debur a good piece of steel.

On our Twin Belt machine rough on the left 200 grit, exact angle match on the right with a 600 grit, Debur minimal

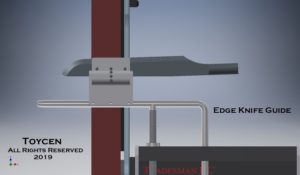

With this enhanced freehand approach, the stroke is captive but you won’t get cornered by your set up when doing a long blade or a large curved tip. our supermagnets let you rotate the knife to follow a tip radius

With the Tradesman edge running a 600 grit edge grind at 150 surface feet on machined platens allows for perfectly straight hand fed angles

With the DC whisper drive, in our shop you can hear the clock ticking in the background while running twin belts, this also means you can hear when the blade contacts the belt.

Just like our tool grinders.

Its a new day

Jeff

Contact Us

Contact Us  Phone

Phone