Resin Bond Wheels Diamond or CBN for Controllable Burr development — Next Post Deburring with resin bond and Composite materials

Resin Bond wheels are a nice alternative to expensive Plated bond wheels that wear out.

Available in CBN of Diamond

KKnives Switzerland on Resin bond wheels

We Agree !

They are not as aggressive as belts or coarse wheels for initial bevel fabrication on a dull blade.

However for what we will call edge prep ( final passes heading to a manageable burr) they are hard to beat.

CBN can be run Dry at the right speed and concentration

Our Diamond wheels are meant to be Run wet

Tradesman Resin bond wheels are designed specifically for Edge Apex or Tormek Machines.

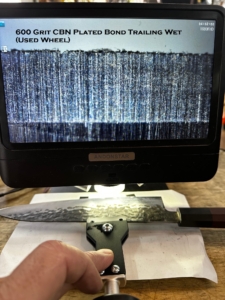

Aggressive Grind Test:

Damascus Steel Blade fairly hard

600 Grit CBN Plated bond one new wheel, one well broken in wheel 220 CBN Resin bond

USED 600 Grit CBN Plated Bond New 600 CBN Plated Bond 220 Grit CBN resin Bond

Victorinox Chef Knife:600 Grit CBN Plated bond, In service not new wheel and the220 CBN Resin bond

600 grit CBN Wet Trailing 220 Resin bond Wet Trailing

The 200 Grit wheel is fast enough to use for final edge prep grind and get to a manageable burr

Bottom line the 220 grit CBN leaves less burr than the 600 Grit plated bond, a nicer finish AND

it will never were out, or get dull.

Next Deburring with a Fine grit Resin Bond wheel

Jeff

Background on Resin bond wheels

Superabrasive grinding wheels have two equally important components. While the grit, (diamond or CBN) does the work, it couldn’t function without a partner holding it in place. In the case of resin bond grinding wheels, that partner is phenolic resin.

The hardness of the phenolic, along with grit size and concentration, determines wheel life, material removal rate, and final surface finish. CDT controls these three parameters precisely, allowing users to match a wheel to the particular workpiece material and type of grinding operation. However, selecting the best wheel depends on understanding the relationship between hardness, grit size and concentration and the wheel wear mechanism.

WHEEL WEAR MECHANISMS

As grit cuts through the workpiece material the edges become dull. Allied to that, chips from the cutting process erode the resin, releasing old grit and exposing fresh edges. The rate at which fresh grit is exposed is critical. Dull edges tend to rub against the workpiece, cutting forces go up and more heat is generated, perhaps burning the workpiece. Conversely, if grit is released early the grinding wheel is wearing faster than necessary, resulting in more frequent replacement.

HARDNESS

Hard workpiece materials, like ceramics and carbides, tend to dull cutting edges quickly, yet because the chips are small and brittle, resin wear is low. In this situation, to ensure a sufficient supply of fresh new cutting edges it’s best to use a softer wheel.

Softer materials, like steels and high nickel alloys, (which should be ground with CBN rather than diamond,) produce longer, more ductile chips. These erode the resin faster which, in a soft wheel, results in excessive wear.

Manufacturers of resin bond grinding wheels adjust hardness by varying the mix of fillers in the phenolic resin. The resulting wheel hardness is expressed on a scale from A (softest) to Z (hardest) although superabrasive wheels are generally available just for the range from O through U. If a wheel outside of this range is thought necessary, consult with product specialists here at CDT.

CONCENTRATION

This refers to the proportion of superabrasive grit in the resin and is expressed on a scale of 25, 50, 75, and 100. The highest value indicates a weight to volume ratio of 72 carats per cubic inch, which works out to about 25% by volume.

A higher concentration means more cutting points, which results in faster material removal, but also increases wheel cost. Concentration also affects surface finish: a lower concentration would typically be used for finishing than for roughing.

GRIT SIZE

Larger abrasive particles remove more material on each pass, so coarser grits are used for rough machining and when grinding softer materials. Smaller particles lower cutting forces, so are used for harder materials as well as finishing operations.

MATCH THE WHEEL TO THE WORKPIECE

The choice of grinding wheel depends on the nature of the workpiece material and whether roughing or finishing. Harder materials generally should be ground with a softer wheel and small grit size. Softer materials are better ground with harder wheels and larger grit. Grit concentration should be chosen to suit the type of grinding operation – roughing or finishing.

Contact Us

Contact Us  Phone

Phone