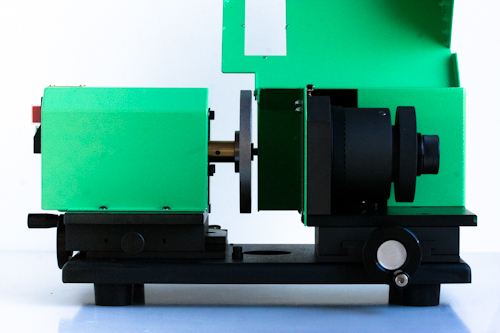

Cut Off and Neck Machine GS-13N

Description

GS-13N Cut Off and Neck Grinding Machine • Cuts off and neck grinds tools • Tool rotates to decrease cutting time and temperature • Collet Type (Chuck type available on request) read moreDescription

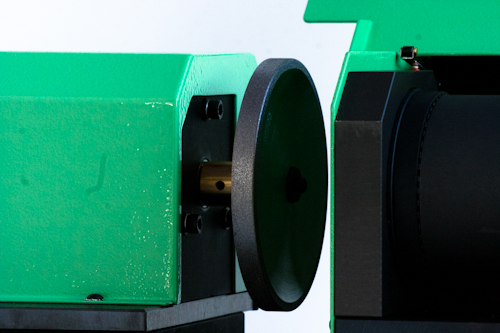

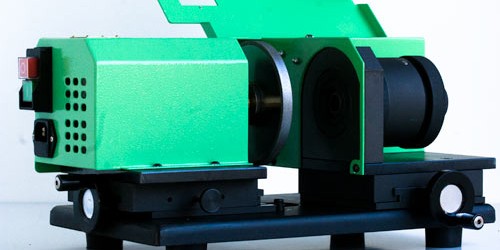

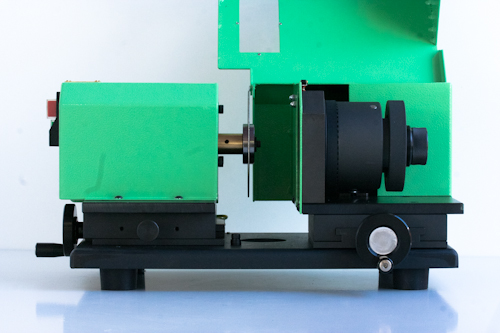

Carbide End Mill Cut Off and Neck Grinding Machine

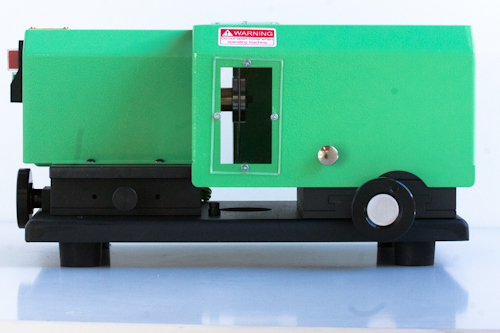

The GS-13N End Mill and Drill Cut-Off Machine is useful to any shop needing to cut off or neck grind high-speed steel or carbide rods or end mills. The GS-13N End Mill and Drill Cut-Off Machine is easy to use, has a small foot print and a heavy construction for industrial use.

• Cuts off and neck grinds tools

• Tool rotates to decrease cutting time and temperature

• Cutting time: approximately 60 seconds

• Includes one CBN or diamond neck wheel, two dia mond cut off wheels (for carbide) and 5 resin cut off wheels (for high speed steel)

• Machine size: 38cm x 23cm x 22cm x 22kg

Options:

GS13 Chuck Type – 3 inch, 3 Jaw Chuck, has 5/8″ thru-spindle and up to 3″ capacity

GS-13 Collet type is ER-32, has 7/8″ thru-bore and 1/8″ to 7/8″ capacity (we recommend this type)

Replacement Neck and Cut Off Wheels

Neck Reduction Wheel for GS-13

Uncategorized

$ 164 (USD)

Cut off wheel for GS-13

Carbide Cut Off

$ 58 (USD)

Call us at 1 (800) 417-2171

Cuttermasters is a machine tool engineering and manufacturing company specializing in Tool and Cutter Grinders. Cuttermaster – Endmill Sharpeners – Drill Sharpeners

Additional information

- Weight

- 28 kg

- Dimensions

- 32 × 32 × 42 cm

Contact Us

Contact Us  Phone

Phone